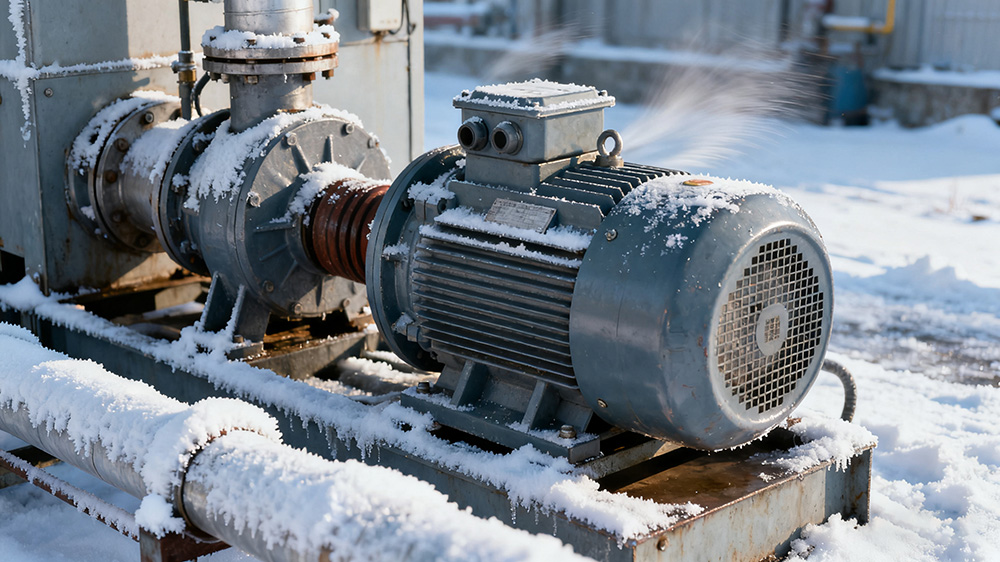

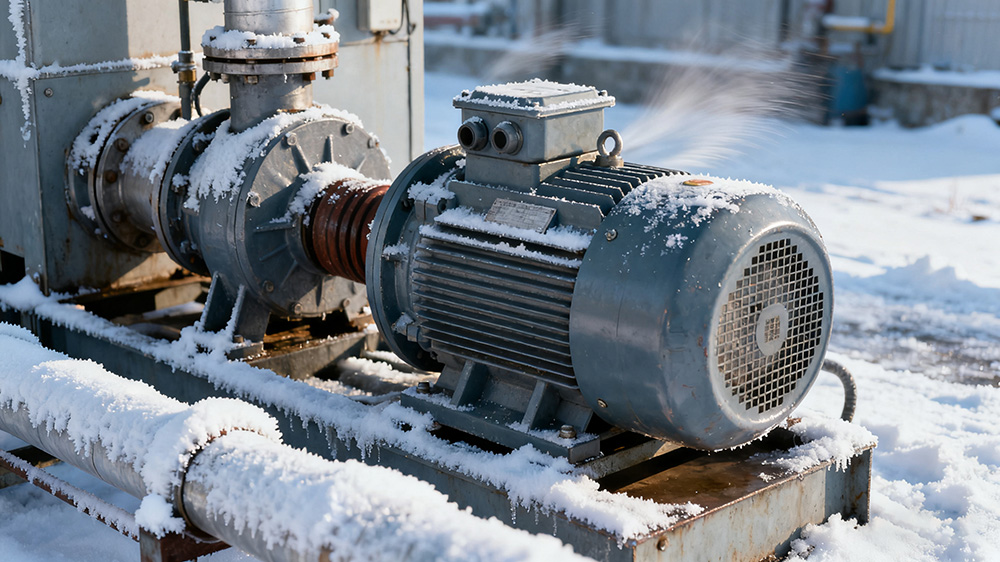

As the core power source for industrial production, transportation, and civilian equipment, the operational performance of motors is highly dependent on ambient temperature. When the ambient temperature falls below -10°C (low-temperature environments are typically defined as -10°C to -40°C, with extreme low temperatures potentially dropping below -40°C), a series of physical and chemical changes occur across multiple systems of the motor, including electromagnetic, mechanical, and insulation systems, directly impacting operational efficiency, reliability, and service life. This paper will analyze the impact mechanisms of low temperatures from the perspective of core performance dimensions and propose targeted optimization solutions.

1、The Impact of Low Temperatures on Motor Insulation Systems: From Performance Degradation to Failure Risks

The motor insulation system is crucial for ensuring the safe operation of windings, primarily composed of materials such as insulating varnish, insulation paper, and insulating sleeves. Its performance is highly sensitive to temperature variations. In low-temperature environments, the changes in the insulation system are mainly manifested as "increased brittleness" and "elevated dielectric loss":

①Degradation of Insulating Material Physical Properties: Low temperatures can advance the glass transition temperature of insulating varnishes (such as alkyd resin varnish and epoxy resin varnish), causing the material to shift from a "flexible state" to a "brittle and hard state," significantly reducing impact and vibration resistance. For example, the tensile strength of ordinary insulating paper decreases by more than 30% at -20°C. If vibration accompanies motor startup, it may lead to cracking of the insulating paper and peeling of the varnish, resulting in reduced insulation resistance between windings and ground or between phases.

②Increased Dielectric Loss and Breakdown Risk: In low-temperature environments, moisture within insulating materials tends to condense into tiny ice crystals, which can disrupt the uniformity of the insulation structure and elevate the dielectric loss factor (tanδ). Data indicates that at -30°C, the dielectric loss of standard motors may reach 2-3 times that at room temperature, while the insulation breakdown voltage decreases by 15%-20%. Prolonged operation under such conditions can easily lead to winding short-circuit failures.

③Accelerated Insulation Degradation at Low Temperatures: Repeated low-temperature start-stop cycles cause insulation materials to undergo a "low-temperature embrittlement-room temperature recovery" cycle, leading to the formation and gradual propagation of microcracks within the material, ultimately reducing the designed lifespan of the insulation system. For instance, motors frequently starting and stopping in an -25°C environment may experience insulation lifespans reduced to only 60%-70% of those in room-temperature conditions.

2、The impact of low temperature on motor conductors and electromagnetic performance: decreased efficiency and increased losses

The electromagnetic performance of a motor depends on the conductivity of the conductor (copper or aluminum winding) and the magnetic permeability of the magnetic core. Low temperature can indirectly affect the output efficiency and energy consumption of the motor by changing the physical parameters of the material

①Abnormal changes in conductor resistance: Although the resistance of copper and aluminum decreases with temperature (theoretically, low temperature can reduce copper loss), in actual low temperature environments, if the insulation layer of the winding is brittle and falls off, it may cause the conductor to come into contact with the outside air, and the moisture in the air condenses on the surface of the conductor, forming a "small conductive channel". In this case, the "effective resistance" of the conductor will actually increase, especially in low temperature environments with high humidity (such as -15 ℃, relative humidity above 80%), where copper loss may increase by 10% -15% and motor temperature rise may be abnormal.

②Attenuation of magnetic core permeability: Motor magnetic cores are often made of stacked silicon steel sheets, and the permeability (μ) of silicon steel sheets decreases with decreasing temperature. At -30 ℃, the magnetic permeability of ordinary 30Q130 silicon steel sheets will decrease by about 20%, resulting in an increase in the excitation current of the motor (which may increase by 25% -30%) and a decrease in the power factor (cos φ). For example, a motor with cos φ=0.85 at room temperature may drop to 0.7-0.75 at -35 ℃, which not only reduces output efficiency but also increases reactive power losses in the power grid.

③Significant deterioration of starting performance: Low temperatures can cause a decrease in motor starting torque and an extension of starting time. On the one hand, the decrease in magnetic permeability of the magnetic core leads to insufficient electromagnetic torque during startup; On the other hand, the viscosity of bearing grease increases at low temperatures (as described later), which increases mechanical resistance. Data shows that in an environment of -40 ℃, the starting torque of a regular motor may only be 65% -70% of room temperature. If the load torque remains unchanged, it is prone to problems such as "starting failure" or "winding overheating during starting".

3、The impact of low temperature on the mechanical structure of motors: from operational lag to component damage

The mechanical structure of the motor (bearings, shaft system, housing) will face dual challenges of "material shrinkage" and "lubrication failure" in low temperature environments, directly affecting operational stability:

①Failure of bearing lubrication system: Motor bearings are often lubricated with grease. Ordinary grease (such as lithium based grease) will "solidify" below -20 ℃, with a sharp increase in viscosity (possibly more than 10 times that of room temperature), resulting in a significant increase in frictional resistance between the bearing rolling elements and the inner and outer rings. During operation, it not only produces abnormal noise (usually exceeding 85dB), but also causes the bearing temperature to rise. If operated for a long time, it may lead to bearing raceway wear, rolling element breakage, and cause motor "jamming" faults.

②Abnormal shrinkage and fit clearance of metal components: The linear expansion coefficient of metal components such as motor shafts and bearing seats (mostly carbon steel or cast iron) shrinks with decreasing temperature, resulting in changes in the fit clearance between components. For example, the interference fit between the motor shaft and the inner ring of the bearing may become a "clearance fit" due to shaft contraction at -30 ℃, resulting in "shaft movement" during operation. This not only increases vibration (vibration acceleration may exceed 1.5mm/s 2), but also causes uneven air gap between the rotor and stator, further exacerbating electromagnetic noise and losses.

③Damage to the shell and sealing structure: If the motor shell is made of ordinary steel plate, it will exhibit "low-temperature brittleness" in extreme low temperature environments (such as below -40 ℃), and its impact resistance will decrease. If it is subjected to external force collision (such as equipment handling, wind and snow impact), the shell is prone to cracking. At the same time, the sealing strip of the shell (such as EPDM rubber) will harden and shrink at low temperatures, leading to a decrease in sealing performance. External moisture and dust will enter the interior of the motor, accelerating the deterioration of insulation and conductors.

4、Optimization strategies for motor performance in low-temperature environments

To address the multidimensional impact of low temperatures on motor performance, solutions need to be developed from three levels: material selection, structural design, and operation and maintenance

①Insulation system material upgrade: Select insulation materials with excellent low-temperature toughness, such as replacing ordinary insulation paint with "low-temperature modified epoxy resin paint" (glass transition temperature can be as low as -40 ℃), and using "polyimide film composite paper" for insulation paper (maintaining good flexibility at -60 ℃); At the same time, the winding is subjected to "vacuum impregnation" treatment to reduce the gaps inside the insulation and prevent moisture condensation.

②Optimization of conductor and magnetic core adaptation: The surface of the conductor can be coated with a "low-temperature anti condensation coating" (such as polytetrafluoroethylene coating) to prevent moisture adhesion; The magnetic core is made of silicon steel sheets with reduced low-temperature permeability attenuation (such as 35W250), or a "low-temperature insulation layer" (such as glass wool insulation layer) is pasted on the surface of the magnetic core to reduce the influence of temperature fluctuations on the magnetic conductivity performance.

③Mechanical structure and lubrication improvement: "Low temperature special lubricating grease" (such as polyurea based lubricating grease, suitable for temperature range of -40 ℃ to 120 ℃) is selected for bearings, and the filling amount of lubricating grease is appropriately increased (10% -15% more than normal temperature environment); Perform "low-temperature compensation design" on the fit clearance between the shaft and the bearing, such as increasing the interference fit at room temperature by 0.01-0.02mm to counteract the effect of low-temperature shrinkage; The shell is made of "low-temperature tough steel" (such as Q355ND), and the sealing strip is made of "silicone rubber material" (can be used normally from -60 ℃ to 200 ℃).

④Adjustment of operation and maintenance strategy: Motors in low-temperature environments need to be preheated in advance. External preheating devices (such as PTC heaters) can be used to raise the internal temperature of the motor to 5 ℃ -10 ℃ before starting; Regularly (every 3 months) check the condition of the lubricating grease, and replace it promptly if it solidifies or deteriorates; Install a "thermal insulation cover" on the motor casing and install a "humidity sensor" inside. When the humidity exceeds 75%, activate the dehumidification device to prevent moisture condensation.

The impact of low temperature environment on motor performance is not a single dimensional issue, but involves a chain reaction of insulation, electromagnetic, and mechanical systems. In scenarios such as industrial automation, new energy vehicles (in low-temperature areas), and cold chain logistics that require low-temperature operation, ignoring the impact of low temperature on motors not only leads to a decrease in motor efficiency and an increase in energy consumption, but may also cause serious consequences such as equipment shutdown and safety accidents. Through the combination strategy of "material upgrade+structural optimization+refined maintenance", the impact of low temperature on motor performance can be effectively alleviated, ensuring long-term stable operation of the motor in low temperature environments.

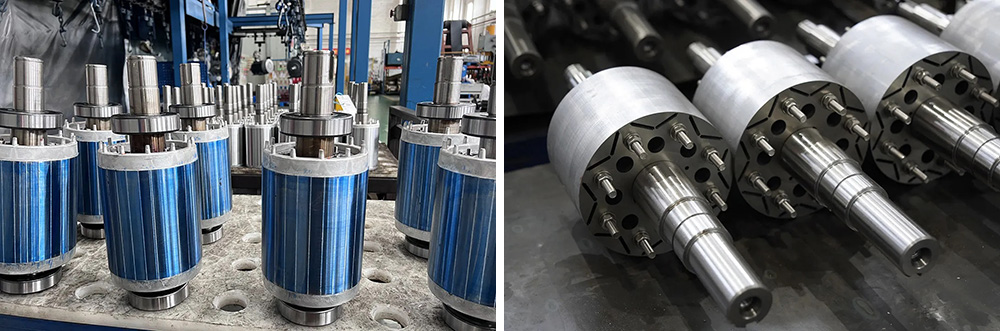

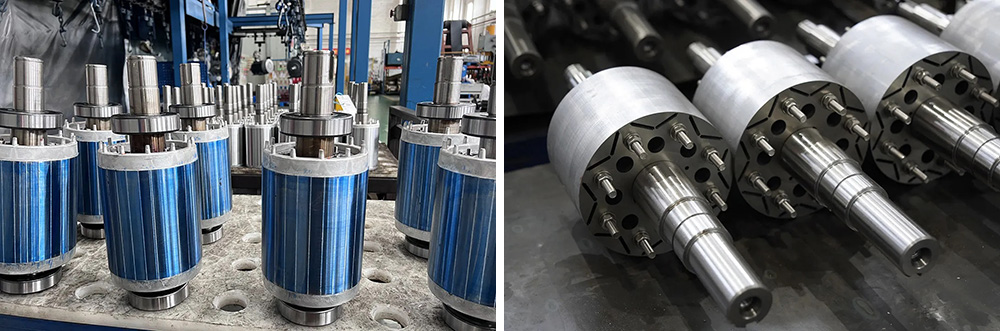

Hengda Electric has always been dedicated to the research and development, production, and service of various types of motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.